| 0574-65127588 18158205599 |

When the liquid is under the working pressure, the liquid molecular structure the metal surface are mutually effective, the "polar molecules" often contained in the hydraulic oil are arranged in an inseparable neat order on the metal surface, resulting in a solid boundary layer floating oil between the load surface the hydraulic seal, causing huge adhesion to the load surface. The damping plane bearing supplier's liquid plastic film always exists between the hydraulic seal the repeated movement surface. It also has a certain sealing effect, it is very important to moisten the protruding surface of fitness movement. But it's dangerous for the leak. However, when the repeatedly moving diameter is pulled out, the liquid plastic film on the shaft will be pulled out together with the shaft. Because of the "scrubbing" effect of the hydraulic seal, when the repeatedly moving shaft retracts, the liquid plastic film will be kept outside by the sealing components. With the increase of the frequency of repeated movement travel arrangement, the larger the liquid retained to the outside will be, finally liquid drops will be produced, which is the leakage of repeated movement sealing equipment. Because the viscosity of gear oil decreases with the increase of temperature, the thickness of floating oil the supplier of forson suspension bearing is relatively reduced. Therefore, when hydraulic machinery is started at ultra-low temperature, the leakage is very large at the beginning of fitness exercise. With the rise of temperature caused by various damages in the whole process of fitness exercise, the leakage amount has a development trend of gradual reduction.

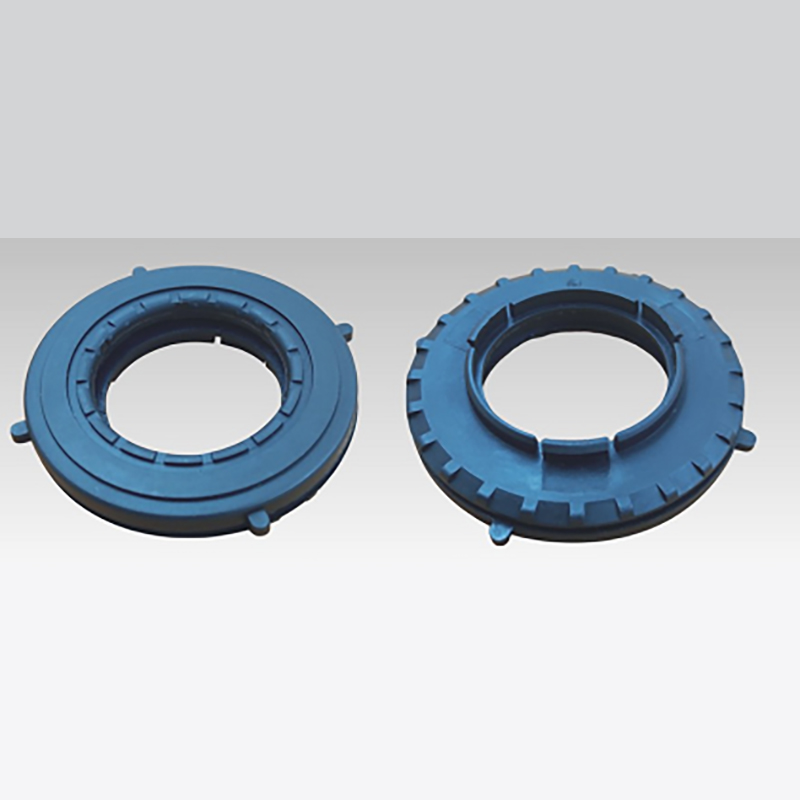

O-ring as reciprocating sealing, compact structure, small size, can reduce the cost of components. Key uses are:

1) In the bottom pressure hydraulic parts, it is generally limited to short stroke arrangement medium level working pressure of 10MPa.

2) Small diameter, short stroke arrangement in which the horizontal working pressure of hydraulic press vane pump.

3) Pneumatic vane pump pneumatic cylinder.

4) It is used as polyurethane elastomer in combined reciprocating dynamic sealing equipment.

The O-ring is the most suitable place for reciprocating dynamic sealing, such as small diameter, short stroke arrangement, low medium working pressure of suspension bearing suppliers, pneumatic cylinder, pneumatic vane pump other repetitive motion components. In hydraulic parts, O-ring is used as the key dynamic sealing property, which is generally limited to short stroke arrangement low medium working pressure of 10MPa. The O-ring should be used as the reciprocating dynamic sealing property with extremely low speed as high pressure reciprocating dynamic sealing property independently. The key is that the friction under such standards is very large, which will cause the sealing performance to be invalid too soon. In all forms of application, it must be based on the rating data information working capacity of hydraulic seals, it must be installed properly to obtain satisfactory characteristics.